UPS boosts dry ice capabilities in preparation for vaccine transport

UPS said it has boosted its dry ice production capabilities in preparation for the task of distributing COVID-19 vaccines that must be kept at freezing temperatures.

As the logistics industry prepares to ship vaccines around the world, experts have raised concerns about a potential dry ice shortage.

Sandy Springs-based UPS said it can now produce as much as 1,200 pounds of dry ice per hour at its U.S. facilities.

The company said the boosted capacity will ensure there’s enough dry ice to pack shipments from its health care facilities in Louisville, Kentucky and Dallas, Texas, as well as Ontario, Canada.

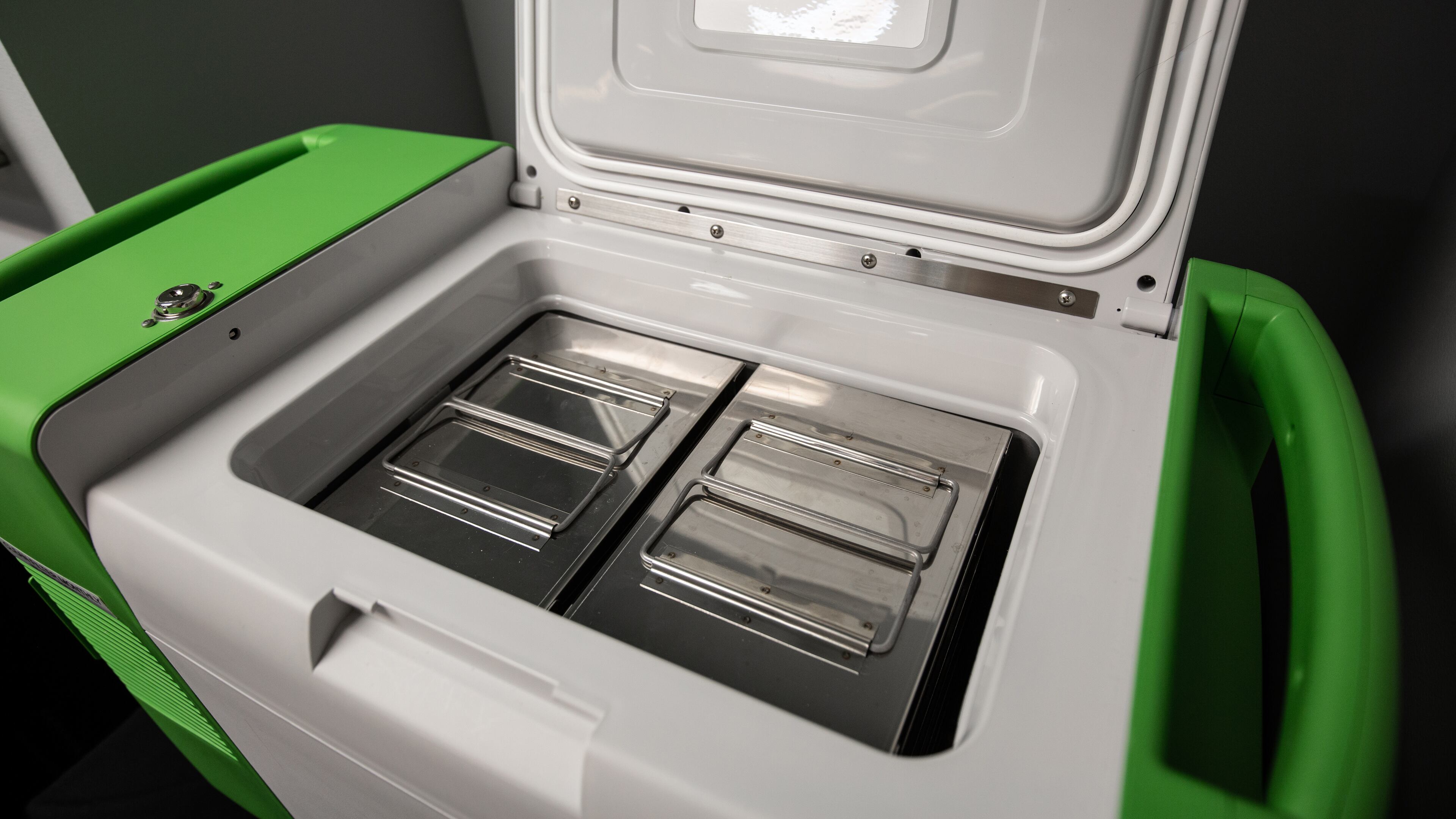

UPS is also partnering with Athens, Ohio-based dry ice freezer manufacturer Stirling Ultracold for portable ultra-low temperature freezers to store vaccines at health care facilities. The freezers can store vaccines at temperatures ranging from minus 20 degrees to minus 80 degrees Celsius.

The partnership “will help ensure vaccines remain effective next year, and for years to come, as future vaccines and biologics are developed,” Stirling CEO Dusty Tenney said in a written statement.

Pharmaceutical firms have announced successes in COVID-19 vaccine trials. AstraZeneca’s vaccine can be stored at refrigerator temperatures. But the Pfizer vaccine must be shipped at ultra-cold temperatures, and the Moderna vaccine requires freezer temperatures for long-term storage, which can add a layer of complexity to the distribution of vaccines, particularly in developing countries.